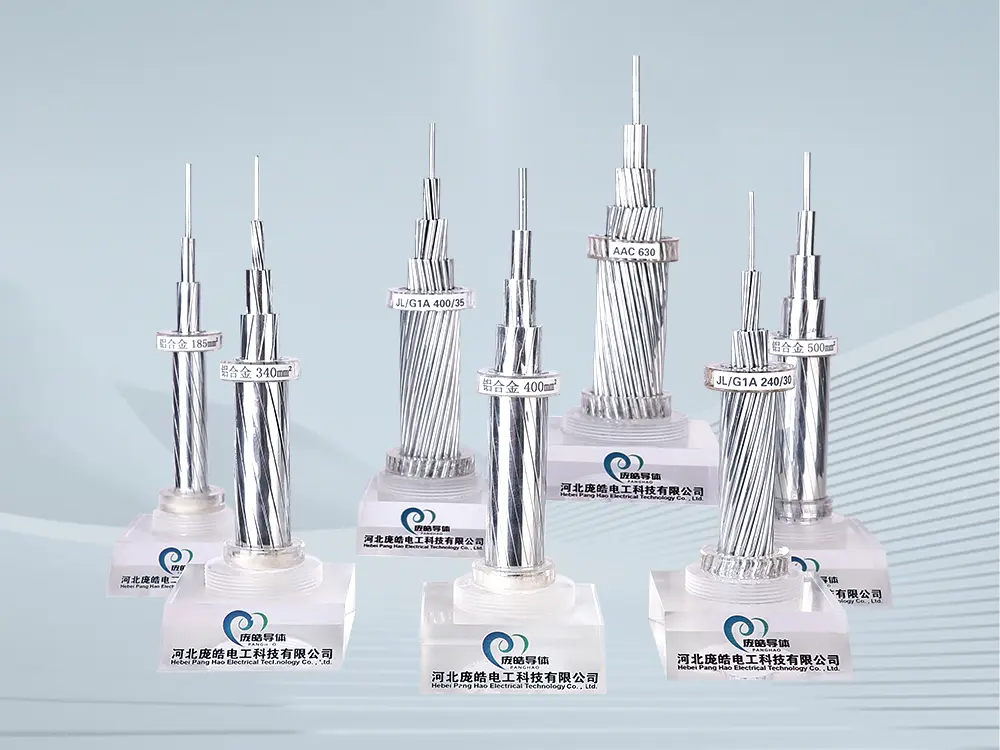

Aluminum Alloy Conductor Steel Reinforced-AACSR(bare conductor)

| Material: | All Aluminum | Standard: | ASTM B 711, as 3607, IEC 61089 |

|---|---|---|---|

| Country Of Oringinal: | China | Test: | 100% |

| Characted: | Bare Conductor | Nearest Port: | Tianjing or Qingdao Port |

Aluminum Alloy Conductor Steel Reinforced-AACSR(bare conductor)

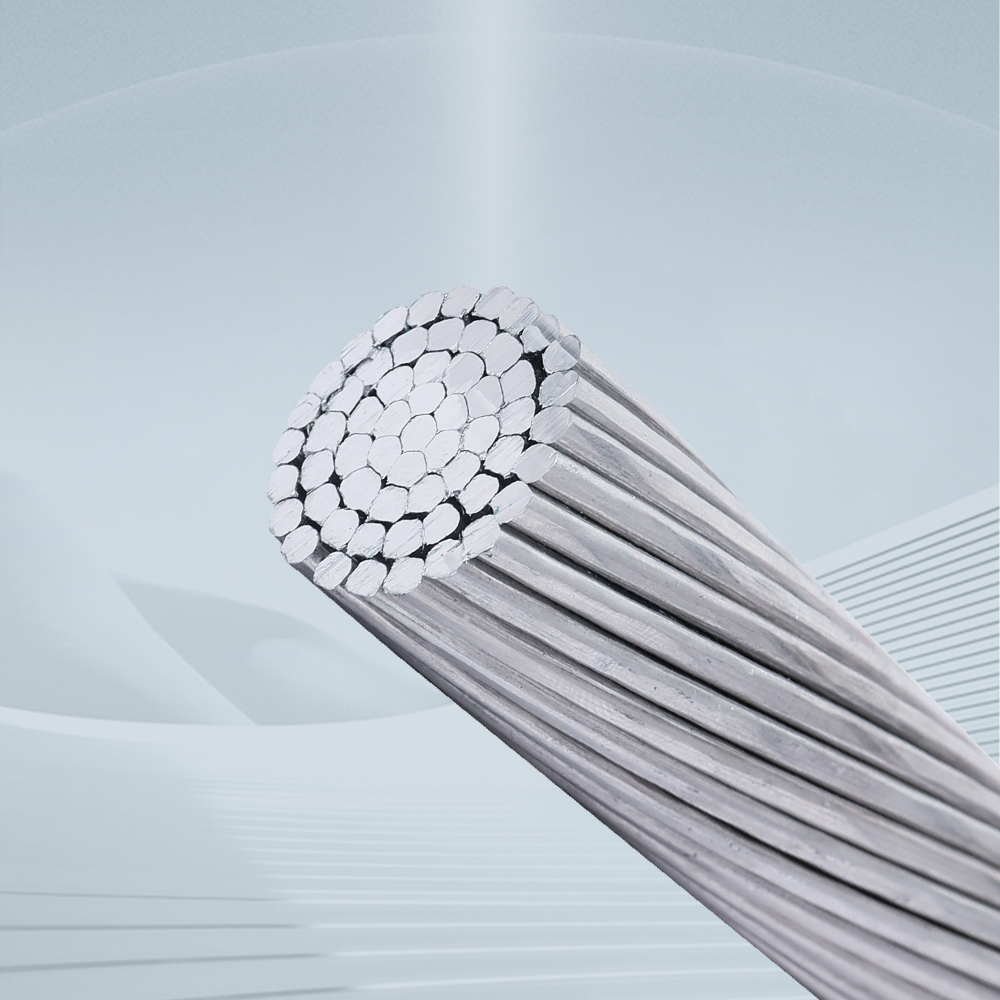

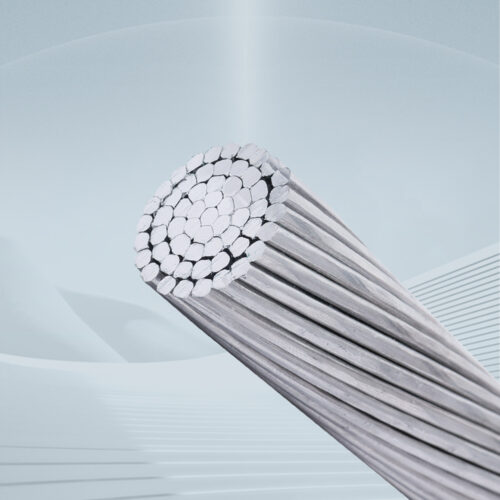

1: APPLICATION:AACSR is a concentrically stranded conductor composed of one or more layers of Aluminium-Magnesium-Silicon alloy wire stranded over a high-strength zinc coated (galvanized) steel core.

AACSR Conductors have approx. 40% to 60% more strength than comparable standard ACSR with only 8 to 10% decrease in conductivity.

2: Construction: Aluminum wires are concentrically stranded.

3: All Aluminum Conductor meets or exceeds the following standards: ASTM B 711, as 3607, IEC 61089.

Products parameters

| LL ALUMINUM ALLOY CONDUCTOR STEEL REINFORCED (AACSR) – ASTM B 711 | ||||||||||||

| Sectional Area | Stranding | Diameter of Complete Conductor |

Weight | Rated Strength |

DC Resistance @ 20°C |

Current Capacity | ||||||

| Alloy Nominal |

Conductor size | Total | No. of Wires | Wire diameter | ||||||||

| Aluminum | Steel | Aluminum | Steel | 75°C | 85°C | |||||||

| (mm²) | (mm²) | (mm²) | (No.) | (No.) | (mm) | (mm) | (mm) | (Kg/Km) | KN | (Ω/Km) | (Ampere) | (Ampere) |

| 1250 | 102 | 1352 | 84 | 19 | 4.35 | 2.61 | 47.85 | 4255 | 490 | 0.0271 | 913 | 1221 |

| 1120 | 91 | 1211 | 84 | 19 | 4.12 | 2.47 | 45.31 | 3816 | 439 | 0.03021 | 866 | 1151 |

| 1000 | 81 | 1081 | 84 | 19 | 3.89 | 2.33 | 42.77 | 3400 | 391 | 0.03388 | 818 | 1079 |

| 900 | 73 | 973 | 84 | 19 | 3.69 | 2.21 | 40.57 | 3060 | 355 | 0.03766 | 775 | 1017 |

| 800 | 101 | 901 | 54 | 19 | 4.34 | 2.6 | 39.04 | 3003 | 363 | 0.04234 | 722 | 943 |

| 710 | 90 | 800 | 54 | 19 | 4.09 | 2.45 | 36.79 | 2664 | 322 | 0.04768 | 678 | 881 |

| 630 | 80 | 710 | 54 | 19 | 3.85 | 2.31 | 34.65 | 2365 | 286 | 0.05381 | 635 | 821 |

| 560 | 71 | 631 | 54 | 19 | 3.63 | 2.18 | 32.68 | 2104 | 257 | 0.06053 | 596 | 766 |

| 500 | 63 | 563 | 54 | 19 | 3.43 | 2.06 | 30.88 | 1878 | 229 | 0.06779 | 560 | 716 |

| 450 | 59 | 509 | 54 | 19 | 3.26 | 1.98 | 29.46 | 1706 | 215 | 0.07505 | 530 | 675 |

| 400 | 91 | 491 | 30 | 19 | 4.12 | 2.47 | 28.83 | 1818 | 237 | 0.08437 | 300 | 382 |

| 400 | 65 | 465 | 26 | 7 | 4.43 | 3.45 | 28.07 | 1616 | 207 | 0.084 | 299 | 379 |

| 355 | 81 | 436 | 30 | 19 | 3.88 | 2.33 | 27.17 | 1614 | 211 | 0.09513 | 297 | 376 |

| 355 | 58 | 413 | 26 | 7 | 4.17 | 3.24 | 26.4 | 1430 | 183 | 0.0948 | 289 | 365 |

| 315 | 72 | 387 | 30 | 19 | 3.66 | 2.2 | 25.64 | 1438 | 190 | 0.10691 | 335 | 422 |

| 315 | 46 | 361 | 26 | 7 | 3.93 | 3.06 | 24.9 | 1272 | 163 | 0.10673 | 333 | 419 |

| 280 | 65 | 345 | 30 | 7 | 3.45 | 3.45 | 24.15 | 1286 | 171 | 0.12032 | 350 | 440 |

| 280 | 46 | 326 | 26 | 7 | 3.7 | 2.88 | 23.44 | 1127 | 144 | 0.12041 | 348 | 436 |

| 250 | 58 | 308 | 30 | 7 | 3.26 | 3.26 | 22.82 | 1149 | 156 | 0.13476 | 367 | 460 |

| 250 | 41 | 291 | 26 | 7 | 3.5 | 2.72 | 22.16 | 1008 | 129 | 0.13457 | 365 | 456 |

| 224 | 52 | 276 | 30 | 7 | 3.08 | 3.08 | 21.56 | 1025 | 139 | 0.15097 | 385 | 480 |

| 224 | 36 | 260 | 26 | 7 | 3.31 | 2.57 | 20.95 | 901 | 118 | 0.15046 | 383 | 477 |

| 200 | 47 | 247 | 30 | 7 | 2.91 | 2.91 | 20.37 | 915 | 124 | 0.16912 | 404 | 502 |

| 200 | 32 | 232 | 26 | 7 | 3.13 | 2.43 | 19.81 | 805 | 106 | 0.16826 | 402 | 499 |

| 180 | 42 | 222 | 30 | 7 | 2.76 | 2.76 | 19.32 | 823 | 112 | 0.188 | 428 | 531 |

| 180 | 29 | 209 | 26 | 7 | 2.97 | 2.31 | 18.81 | 731 | 95.1 | 0.18688 | 423 | 524 |

| 160 | 38 | 198 | 30 | 7 | 2.61 | 2.61 | 18.27 | 736 | 106 | 0.21024 | 447 | 553 |

| 160 | 26 | 186 | 26 | 7 | 2.8 | 2.18 | 17.74 | 646 | 85.6 | 0.21026 | 444 | 548 |

| 140 | 33 | 173 | 30 | 7 | 2.44 | 2.44 | 17.08 | 643 | 87.4 | 0.24055 | 470 | 579 |

| 140 | 23 | 163 | 26 | 7 | 2.62 | 2.04 | 16.6 | 565 | 75 | 0.24014 | 466 | 574 |

Features:

Offers optimal strength for line design.

Improved strength to weight ratio.

Ideal for extra long spans and heavy load conditions.

Excellent resistance to corrosion.

Package

Package in Export Wooden or Steel Wooden or Steel Drums.